In-house Production

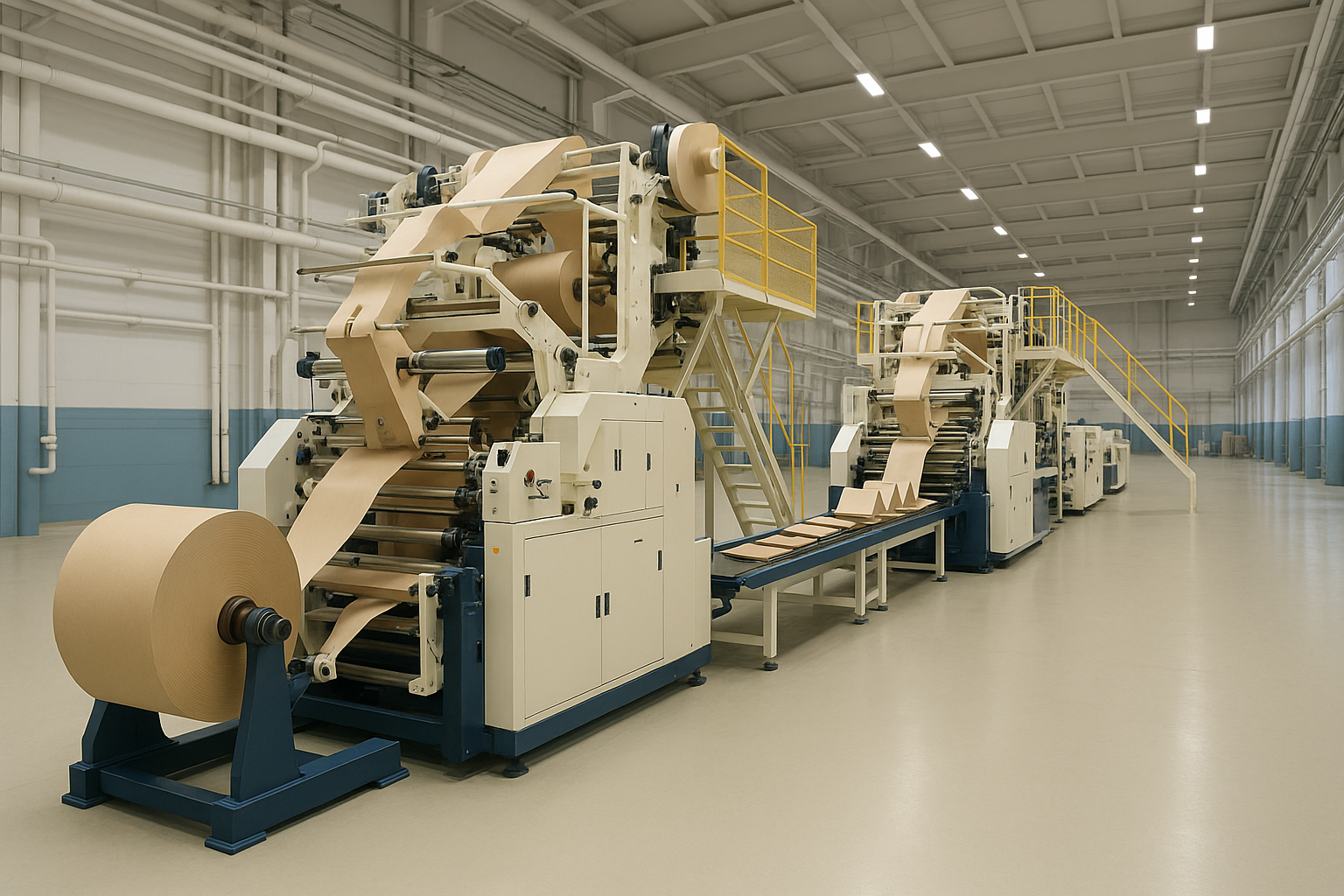

Dual Machinery Setup

140 bags per minute

Got questions or need assistance with your Industry needs?

Our facility is equipped with a state-of-the-art dual machinery setup designed to optimize the production of mailers and paper carry bags. This advanced setup allows us to maintain high-speed production of up to 140 bags per minute, ensuring both efficiency and precision. By integrating in-house slitting and rope-making capabilities, we maintain full control over quality at every stage, from raw material to finished product. This approach enables consistent output, reduced defects, and faster turnaround times, giving our clients reliable, high-quality products tailored to their needs.

The primary goals of the Total Quality Management (TQM) project are to enhance product quality, reduce defects, and foster a culture of continuous improvement.

We manufacture mailers and paper carry bags with custom sizes and designs.

Our dual machinery setup, along with in-house slitting and rope-making, ensures consistent quality in every batch.

Yes, our high-speed production allows us to efficiently manage bulk orders.

Absolutely! We can tailor bags to specific dimensions, prints, and rope types.

We cater to retail, e-commerce, food packaging, and corporate clients seeking premium paper bags.

Join us to experience cutting-edge industrial solutions that drive innovation, lasting success.

Copyright © 2025 All Rights Reserved.